|

CFB A1000 A movement for a new age: the automatic CFB A1000 caliber from Carl F. Bucherer.

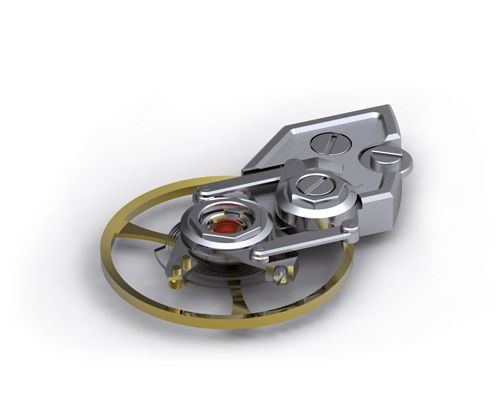

One of the unwritten laws of the Swiss watchmaking industry is that only brands that make at least one movement entirely of their own in-house may use the prestigious name Manufacture. At Carl F. Bucherer, with their own workshops for the manufacture of movements and additional mecha-nisms, this is the case. Carl F. Bucherer Technologies SA in Ste-Croix is both a factory of creative thought and a compe-tence center for research, development and production, with comprehensive technological know-how and the most modern of infrastructures at its disposal. Since 2005, Carl F. Bucherer has been working on an unusual self-winding caliber of its own design. It is called the CFB A1000. This Manufacture movement goes back to the basic decision to add a new facet to the multifarious Carl F. Bucherer watch collection that would demand the highest level of technical expertise and craftsmanship. Putting the company’s philosophy into practice on a broad scale literally meant it had to create its own watch move-ments. From the very start, the company expressly ruled out the idea of copying an existing movement that was no longer protected by patent. And it soon decided to go ahead with a revolutionary new automatic movement with unique design features. The list of specifications also included a range of different targets, such as – the use of existing, tried-and-tested technologies such as a classic regulatory system, a Swiss club-tooth lever escapement, and a traditional going train with jeweled bearings – a progressive caliber design with an unimpeded view of the bridges, bars and other components – a platform principle, which would facilitate the addition of new features to the movement as required – high reliability – semi-industrial production of the raw movement The CFB A1000 automatic caliber fulfils all these require-ments without exception. Apart from this, the technicians and watchmakers at Carl F. Bucherer have added a whole string of unusual and unconventional features. Peripheral winding rotor. One of the first questions that arose when designing the automatic caliber was where to place the rotor. Looking back through the history of watchmaking, there were four distinct possibilities: 1. To mount it centrally, which means that the rotor then moves over the entire surface of the movement. This design, which has proven itself time and time again, has the disadvantage that it always partially obscures the view of the movement. It also makes it more difficult to fit additional modules on the rotor side. 2. To mount it eccentrically, above the movement. Here we face the same problems as with the central rotor. 3. To integrate a micro-rotor into the movement itself. This system conceals nothing but because of its design calls for smaller components. In order to achieve sufficient winding output with a micro-rotor, the rotor itself needs to be very heavy. However, this leads to greater wear and increased vulnerability to shock. 4. To have the rotor revolving around the edge of the movement. In view of the exacting demands on its design, this last type of rotor arrangement is the most infrequently found of the four possibilities. It combines the technical advantages of the centrally mounted rotor with the optical virtues of the micro-rotor. With the CFB A1000 caliber, Carl F. Bucherer consciously chose the fourth variety, fully aware of the fact that many of its features would have to be redesigned from the bottom up. Unlike earlier versions of this design, the peripherally positioned rotor with the Dynamic Shock Absorption (DSA) system – which has been registered for patent – has an efficient shock-absorption system. The rotor bearing is built to withstand even the most exacting conditions by means of DLC-coated rollers, which are themselves mounted on ball bearings. The latter, which are made of ceramic, make the system virtually maintenance-free. The abbreviation DLC stands for diamond-like carbon, which is an extremely hard (diamond-like) and resistant carbon coating. This process has been reliably used in the manufacture of surgical instruments and other highly acclaimed components for some time now. DLC is considerably harder and more resilient than more commonly found PVD coatings, and adheres particularly well to stainless steel. The thickness of the coating, which can be applied at a maximum of 250 °C, is around one thousandth of a millimeter. Its hardness is 2000 Vickers, so several times harder than that of steel. Dynamic Shock Absorption (DSA) protects the rotor against impacts. In the CFB A1000 caliber, the ball bearing / roller assemblies are mounted on rocking bars, which are precisely positioned by springs. The setting of these rocking bars takes place through a cam. The new dynamic shock absorption system (DSA) is highly efficient. A transmission wheel transfers the rotor’s kinetic energy to the winding mechanism. Carl F. Bucherer has equipped this transmission wheel with two Incabloc shock-absorption systems to ensure that its axis does not snap in the event of a sharp impact, but contact with the rotor is always guaranteed. In such a case – by no means unusual for a wristwatch – the walls of the bridge limit the radial displacement of the rotor. Any axial play of the rotor is held in check by special screws. Which prevents the rotor from banging against the bottom of the case. Bidirectional winding. Another of the automatic movement’s outstanding features is the efficiency of the self-winding mechanism. The rotor supplies energy when turning in either direction. The rotor’s movements are polarized by a low-loss winding system. It consists of two clutch wheels with eccentrically mounted clamp rollers. The pair of wheels spring into action reciprocally and are not only simple in design but also very reliable. Central Dual Adjusting System (CDAS) for intelligent precision adjustment. The heart and soul of any mechanical watch is its balance and spring in combination with the escapement. And here, too, Carl F. Bucherer has come up with another innovation, whose patent is pending. In this case it is CDAS, which stands for Central Dual Adjusting System. The main advantages of the intelligent precision adjustment system with its central control element are: – The balance and escapement require adjustment only once. The system is subsequently secured in position to protect it against shocks. – To guarantee the system’s long-term quality, precision adjustment can only be carried out using a special key issued exclusively to authorized service centers. The balance and stem are bearing-mounted at both ends by two identical Incabloc shock absorption systems, which permits optimum setting of the end shake. A modern interpretation of tradition. The design and decoration of the 30-millimeter wide and 4.3-millimeter high basic movement are an expression both of the high-quality technology and the brand philosophy of Carl F. Bucherer. The bridges and bars situated at various levels are exquisitely finished, featuring matt and brushed surfaces with diamond-cut facets. Alternating matt, brushed and polished surfaces ensure the high optical quality of many of the other components. But the main function of any watch movement is to measure and display the time. The CFB A1000 caliber shows the hours and minutes on centrally positioned hands. For the seconds, there is a small hand at 6 o’clock. Needless to say, Carl F. Bucherer will be adding a number of useful functions to the basic movement. These may include a large date, a day display or even a power reserve indicator. |

Invalid Scald ID.

Mechanical automatic movement wound by a bidirectional rotor running around its edge.

- Diameter: 13’’’ or 30 mm

- Height: 4.30 mm

- Functional jewels: 33

- Frequency: 21,600 beats per hour/3 Hz

- Power reserve: approx. 55 hours

- Regulating mechanism: classical

- Escapement: Swiss club-tooth lever escapement